“Recession Is On Its Way” – Dallas Fed Shows Factory Activity Slumps For 9th Straight Month

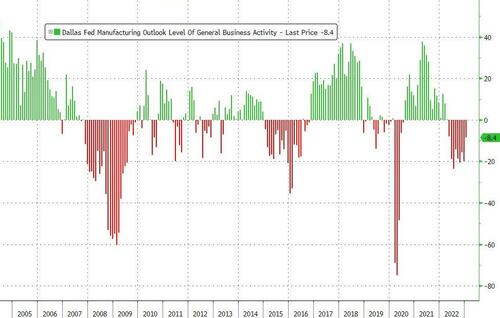

While the headline Dallas Fed Manufacturing Activity Index printed better than expected (-8.4 vs -15.0), it remains in contraction (less than zero) for the 9th straight month (the longest streak since 2016)…

Source: Bloomberg

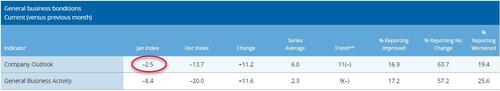

And in fact, the better than expected print was driven solely by ‘hope’ as current production tumbled in January but ‘expectations’ for future production rose…

Source: Bloomberg

Surprisingly, while the outlook for six-months ahead improved (but remains negative)…

…you wouldn’t know it judging by the responses that The Dallas Fed decided to release for publication… notice a pattern?

Food manufacturing

-

We had a customer in the pet food segment significantly decrease its orders due to an inventory backlog.

-

Uncertainty from the overall economic downturn is affecting our long-term strategy.

-

Business is sluggish. We’re seeing increased illiquidity in our customer base.

Beverage and tobacco product manufacturing

-

We are still seeing input costs increase. We had let our gross margin erode over the last couple of years and are now playing catch-up. We are raising prices faster than our inputs increase in a bid to restore an acceptable gross margin. This is resulting in slightly increased dollar sales and increased gross margin, but decreased unit sales. We also had many of our older 3G-based [wireless] credit card readers that we mistakenly thought also had 4G capability stop working due to the phase-out of 3G. New 4G/5G radios are on a several-month back order. Some unknown share of our sales decline is due to lack of credit card readers at the point of sale.

Textile product mills

-

Uncertainty is high. Holiday sales were stronger than expected, but January is slow versus last year. Delivery times are down, but future demand and sales sentiment are low.

Paper manufacturing

-

Activity continues to slip, and selling prices are coming down. We still can’t find any workers and, with our six-month projection, we have quit looking.

Printing and related support activities

-

We have definitely seen a slowdown in activity compared to prior months. It’s as if the spigot got turned off. All our supply-chain constraints are pretty much gone, with delivery times much more like prepandemic times. We have work coming up but right now are very slow and struggling to get our hourly workers even 32 hours per week.

Chemical manufacturing

-

Lost production due to Winter Storm Elliot caused tightening of our inventory levels.

-

We are seeing a slowdown in orders and clients unwilling to hold additional inventory.

Primary metal manufacturing

-

Recession is on its way.

-

The residential building and construction industry has seen a significant decrease in orders across the extrusion industry. Also, imports of aluminum extrusions from South America, Mexico, Malaysia, Vietnam, Turkey and India are at record highs. Mexico is gaining more and more business in the U.S. due to not having to pay Section 232 tariffs, whereas U.S. domestic extruders are paying the tariff via our raw aluminum or billet purchases. If action is not taken, the U.S. aluminum extrusion industry as we know it today will be shutting down capacity and plants.

Machinery manufacturing

-

We are seeing improvement in the business climate. Our competitors are coming to us to supply their customers. Additionally, we are purchasing new machines to add capabilities in our business and further vertically integrate our manufacturing. This will improve our profitability and reduce lead time to produce our products.

-

Order volume has been going down, and we expect the trend to continue. Raw material pricing seems to be stable at the present time.

-

Current federal policies are killing small businesses. From diesel prices to shortages, everything costs so much more.

Computer and electronic product manufacturing

-

We provided significant (10 percent or more) raises in December after a midyear raise in July 2022. We felt that this was essential in order to keep our employees, and we have successfully retained everyone we wanted to keep. We hope not to need to do another round of raises midyear. Since our employees are blue-collar workers, inflation hits them particularly hard, and they are more willing to look for another job for a 10–15 percent pay increase. We are investing in more automation and removing process bottlenecks to increase productivity and reduce lead time.

Transportation equipment manufacturing

-

We have a bleak outlook until the Federal Reserve stops interest hikes and the administration seeks energy independence.

-

We are starting to see some customers pushing delivery out due to market uncertainty.

Furniture and related product manufacturing

-

Requests for bids continue at a steady rate; we have not yet seen a contraction. The only change is, when posting job openings, we actually have people responding—this is a big change and likely a sign of some layoffs after the holidays from other companies. The biggest issues facing our company are increased regulations and contact from federal, state and local entities regarding a variety of topics. Often it feels as a small business that the government does not want us to succeed.

Miscellaneous manufacturing

-

We continue to see large fluctuations in raw material pricing from order to order. Pricing has not corrected from the metals market shutdown in March 2022. Most lead times for raw material remain longer than in previous years.

-

Order volumes remain flat across all markets we serve—automotive OEM [original equipment manufacturers], plumbing and ammunition. Raw material costs and lead times have declined since 2022.

Not exactly a picture of the ‘strong as hell’ economy we hear from The White House?

Tyler Durden

Mon, 01/30/2023 – 11:20

via ZeroHedge News https://ift.tt/umgUIrN Tyler Durden