Amazon has been rolling out machines which automatically scans goods coming down a conveyer belt and boxes them for shipping, according to an exclusive report by Reuters, citing two people who worked on the project.

The ‘latest and greatest’ in automation will replace thousands of workers. After installing the technology in a “handful of warehouses,” the company has considered installing the machines at dozens more – replacing at least 24 workers each at facilities which typically employ more than 2,000 people.

The new machines, known as the CartonWrap from Italian firm CMC Srl, pack much faster than humans. They crank out 600 to 700 boxes per hour, or four to five times the rate of a human packer, the sources said. The machines require one person to load customer orders, another to stock cardboard and glue and a technician to fix jams on occasion. –Reuters

Deployed across 55 US fulfillment centers for standard-sized inventory, this would mean more than 1,300 jobs gone, while Amazon would recover the cost of the program in less than two years at $1 million per machine plus operational expenses.

The plan, previously unreported, shows how Amazon is pushing to reduce labor and boost profits as automation of the most common warehouse task – picking up an item – is still beyond its reach. The changes are not finalized because vetting technology before a major deployment can take a long time. –Reuters

“We are piloting this new technology with the goal of increasing safety, speeding up delivery times and adding efficiency across our network,” said an Amazon spokeswoman in a statement to Reuters. “We expect the efficiency savings will be re-invested in new services for customers, where new jobs will continue to be created.”

Last month Amazon tried to downplay steps towards automation taken at its Baltimore fulfillment center, telling worried employees that a fully robotic future was far off.

A key to its goal of a leaner workforce is attrition, one of the sources said. Rather than lay off workers, the person said, the world’s largest online retailer will one day refrain from refilling packing roles. Those have high turnover because boxing multiple orders per minute over 10 hours is taxing work. At the same time, employees that stay with the company can be trained to take up more technical roles. –Reuters

And while the new machines are 500% faster than a human, the latest round of automation is “truly about efficiency and savings,” according to one of Reuters‘ sources.

Between CartonWrap and another machine known as the “SmartPac,” which mails items in patented envelopes, Amazon’s technology suite will be able to replace most of its human packers, according to the report, which notes that “Five rows of workers at a facility can turn into two, supplemented by two CMC machines and one SmartPac.”

The CMC packing machines have also been used by companies such as Shutterfly Inc, Walmart and JD.com Inc, according to the report. Walmart began using them 3.5 years ago and has deployed the machines across several US locations.

The next challenge – ‘picking’ technology that doesn’t break items.

Interest in boxing technology sheds light on how the e-commerce behemoths are approaching one of the major problems in the logistics industry today: finding a robotic hand that can grasp diverse items without breaking them.

Amazon employs countless workers at each fulfillment center who do variations of this same task. Some stow inventory, while others pick customer orders and still others grab those orders, placing them in the right size box and taping them up. –Reuters

A slew of venture-backed companies and university researchers have been racing to find a solution for picking. While AI can help improve machines’ accuracy, “there is no guarantee that robotic hands can prevent a marmalade jar from slipping and breaking, or switch seamlessly from picking up an eraser to grabbing a vacuum cleaner,” writes Reuters.

Amazon has been testing technology from several vendors which it may someday use for picking, including one from Boston-based startup Soft Robotics, which draws inspiration from octopus tentacles which provide versatile grippers.

Soft Robotics would not comment on its work with Amazon, but says that it has handled a wide and ever-changing variety of products for several large retailers.

Believing that grasping technology is not ready for prime time, Amazon is automating around that problem when packing customer orders. Humans still place items on a conveyor, but machines then build boxes around them and take care of the sealing and labeling. This saves money not just by reducing labor but by reducing wasted packing materials as well.

These machines are not without flaws. CMC can only produce so many per year. They need a technician on site who can fix problems as they arise, a requirement Amazon would rather do without, the two sources said. The super-hot glue closing the boxes can pile up and halt a machine. –Reuters

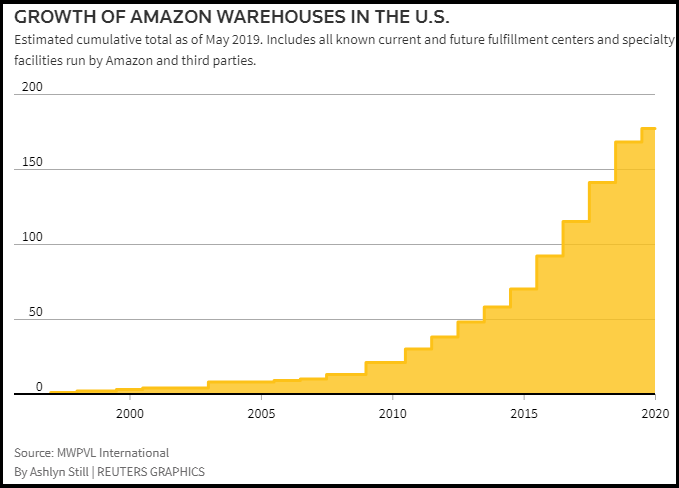

Meanwhile, Amazon has already found the boxing machines to be extremely helpful – while Reuters notes that “the machines have the potential to automate far more than 24 jobs per facility.” The company is also establishing approximately 24 more US fulfillment centers for small and non-specialty inventory, according to logistics consultancy MWPVL International.

“A ‘lights out’ warehouse is ultimately the goal,” said one source.

via ZeroHedge News http://bit.ly/2LDN5F2 Tyler Durden