Baltimore Bridge Collapse May Cost Billions, Dramatically Disrupt Supply Chains

By Noi Mahoney of FreightWaves

The collapse of Maryland’s Francis Scott Key Bridge Tuesday after it was struck by a cargo ship continues to block access to the Port of Baltimore and could disrupt shipping flows across the U.S.

The Singapore-flagged MV Dali container ship collided with the bridge around 1:35 a.m. on Tuesday. At least six people remain unaccounted for, CNN reports. With rescue and recovery operations ongoing, it’s unclear how long debris from the bridge will block the Patapsco River, which leads to the Port of Baltimore.

For the shipping community, the accident will affect maritime lanes as carriers must seek alternative ports of call while the collapsed bridge continues to block the river, experts said.

“Are any container vessels currently trapped in the bay? That is question No. 1,” Sanne Manders, president of international at Flexport, told FreightWaves. “Right now, there are two vessels trapped: the ship that caused the collision and another general cargo container vessel that is currently trapped.”

The Port of Baltimore is the deepest harbor in Maryland’s Chesapeake Bay, with five public and 12 private terminals. The port administration did not immediately respond to a request for comment. Port officials posted on social media that they do not know how long ship traffic in and out of the port will be suspended, although trucks are still being processed.

Manders said another important consideration is the scores of commercial vessels that regularly call at the Port of Baltimore.

“In the next few weeks, 107 vessels will not be able to call that port and will have to divert to other ports,” Manders said. “The question is, are other ports able to absorb that capacity? The reality is that Baltimore is an important port, but for containerized trade, it is relatively small.”

In 2023, the Port of Baltimore handled $80.8 billion in trade, including 1.1 million twenty-foot equivalent units, 1.3 million tons of roll-on/roll-off farm and construction machinery, 11.7 million tons of general cargo, and 847,158 shipments of cars and light trucks.

A number of major companies have distribution warehouses and other facilities at or near the port, including Amazon, FedEx and BMW.

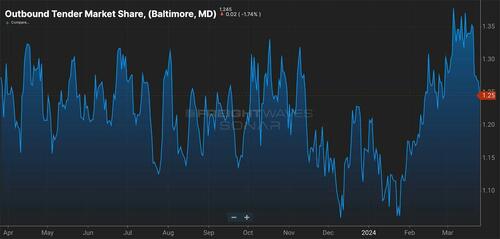

In Maryland, most of the freight is regional, with about 36% of trucking tender volume staying in the state. An additional 22% goes to Pennsylvania and 15% goes to Virginia.

Rachel Shames, vice president of pricing and procurement for CV International, a Norfolk, Virginia-based international logistics and transportation company, wrote in a market update that the collision is expected to create a temporary increase in cargo volume at other East Coast ports.

“The full impacts of this disaster are not yet known, but it’s likely that nearby East Coast ports, including Norfolk, Philadelphia, New York and others will absorb cargo traffic from Baltimore in the short term,” Shames wrote. “This sudden increase in volume may strain operations at other ports.”

Manders said what makes the Port of Baltimore unique is the volume of roll-on/roll-off cargo it handles, such as passenger vehicles, along with agricultural and industrial equipment.

“Then you’re also getting into agricultural exports — rice, sugar, fertilizers, forestry products. It’s pretty big in Baltimore. Then there’s also a big paper industry there and construction materials,” Manders said. “I do think in other commodities and cars, this will have a major impact. There are also some metal exchange warehouses for nickel, tin and copper in Baltimore. Now those can also be moved to other ports, but those are bulky materials, and they don’t move them very easily.”

Jeff Leppert, executive vice president of modal operations at Redwood Logistics, said some of the company’s shipper customers have several ships currently stuck at the port.

“Other impacts include the Port of Baltimore’s fueling depot, which is currently unable to take fueling shipments for the near future,” Leppert told FreightWaves. “The stretch of I-695 that collapsed with the bridge is the only hazmat-approved bridge in the area, so those shipments will have a large diversion in the region and beyond.”

He said all deep-water ships, vessels with a controlling depth of 50 feet, will have to be diverted to ports such as Norfolk and New York/NewJersey.

“We are currently working with all of our shipping customers to find solutions now and for the coming months,” Leppert said.

The Mediterranean Shipping Co. and Zim Integrated Shipping Services Ltd. are two of the Port of Baltimore’s largest shipping lines. Neither company immediately responded to a request for comment from FreightWaves.

Paul Brashier, vice president of drayage and intermodal at ITS Logistics, said the priority right now is to ensure clients are making plans for containers that were originally routed to Baltimore.

“These shipments will be discharged to other ports on the Eastern Seaboard,” Brashier said. “This also means that we must prepare trucking and transload capacity to be able to transport the impacted freight to the appropriate initial location.”

Tyler Durden

Thu, 03/28/2024 – 06:30

via ZeroHedge News https://ift.tt/0KFcVC1 Tyler Durden