A new wave of investments in automation could stimulate the economy after the next recession. By 2030, automation may eliminate 20% to 25% of current jobs (equivalent to 40 million displaced workers), crushing the bottom 90% of Americans the hardest. Some of these investments include the automation of shipping terminals, reported Bloomberg.

At Pier 400 in Los Angeles, North America’s largest shipping terminal, about 1,700 diesel vehicles pass through the facility daily. The terminal is managed by APM Terminals, a segment of A.P. Moller-Maersk A/S, is expected to replace diesel and gasoline engines with electric, and use autonomous software to replace the workforce.

APM has already started to transform Pier 400 into a smart port, which will be several year processes of establishing robots throughout the facility to move containers more efficiently. To do this, APM recently ordered an electric, automated carrier from Finnish manufacturer Kalmar Global, that can perform three tasks: a crane, top-loader, and truck. Not only would the human element be eliminated from the equation, but also 65,000 miles driven by diesel motors would be replaced with electric engines.

The benefits of automation at the port will flow to the highly skilled workers—as well as APM. As a result, automation could significantly increase income inequality in the surrounding community because of the newly displaced workers, stripped of their jobs by robots.

Anthony Armijo, has worked at the terminal for 15 years said, “I just don’t understand what we’re going to be doing in the future,” he said. “I’m an American citizen. You would think they would have a way for us to make a living.”

Automation and clean-energy initiatives are expected to disrupt hundreds, if not thousands, of jobs, at the terminal by 2021.

“Automation is the path of history,” said Dan Sperling, a member of California’s Air Resources Board and professor of civil engineering and environmental science at the University of California, Davis. “The questions are how much automation really makes sense, and how do you deal with the disruption to the workers?”

Wim Lagaay, president and chief executive officer of APM North America, views automation as a way to stay competitive in the global economy.

“If you don’t have a competitive port, you don’t have volumes, you have nothing,” he said. “Jobs will change, jobs will be created, jobs will be eliminated.”

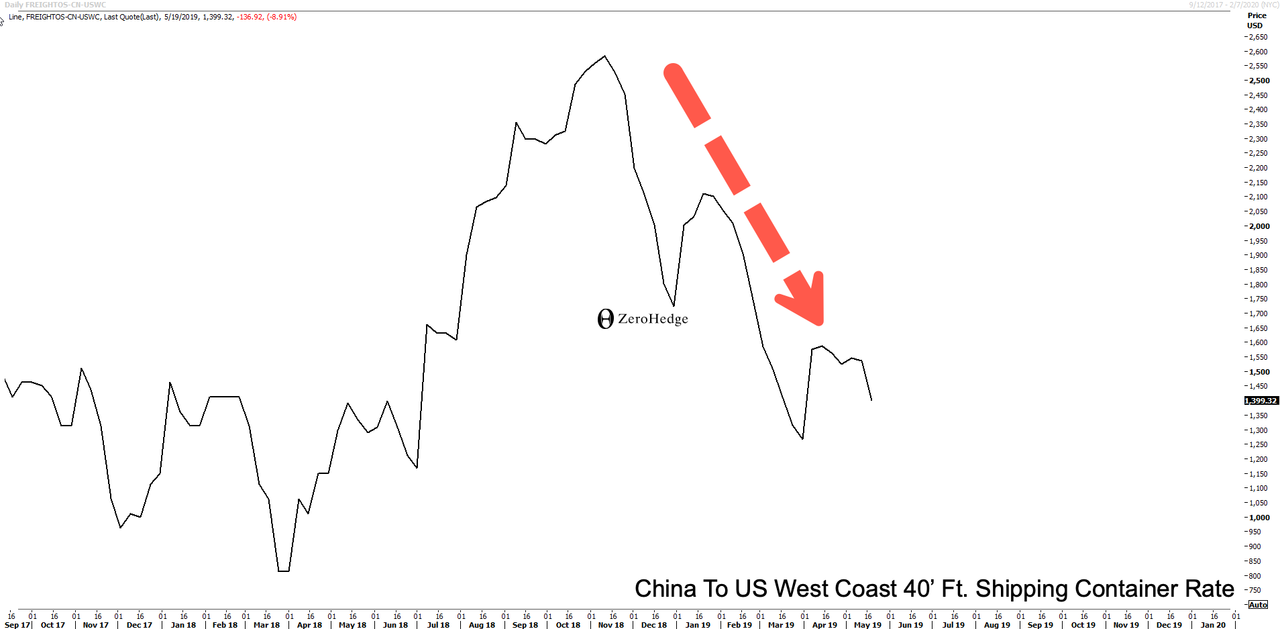

The deepening trade war has led to a slowdown in trade volume at the terminal. Exports to China through Los Angeles and Long Beach crashed by 35%, and imports from China dropped 11.5% in 1Q19, versus 1Q18.

Automation will help the terminal survive the trade war by lowering operating costs, increase productivity, and allow the facility to work 24/7.

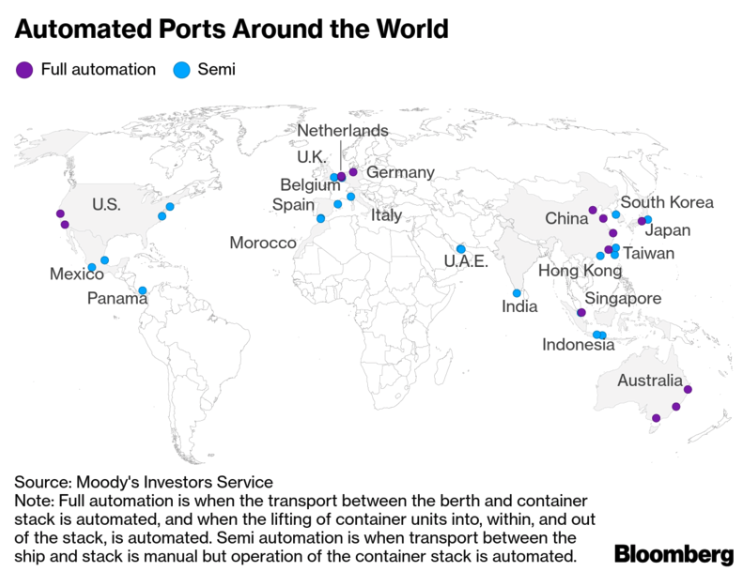

Moody’s Investors Service shows that only 5 of the 44 shipping terminals that are either semi-automated or fully automated are located in the US.

West Coast ports have increased cost pressures and struggle to stay competitive, given their per container costs are 165% higher than East Coast and Gulf Coast ports, according to the Pacific Maritime Association.

The $1.5 billion, fully automated system at Pier 400 will be completed in 2021, will handle more freight and make the terminal more competitive, while cutting pollution.

“The reality is, if you want to be competitive, you do have to go towards automation,” said Lee Klaskow, a Bloomberg Intelligence analyst.

The next phase of automation has begun, and it will accelerate for the next decade. Waves of automation have reshaped the economy in the past, take, for example, agricultural automation allowed farmers to shift to factories, and industrial automation enabled factory workers to migrate to the service sector. Each time, the impact of automation on the economy has created increased volatility in the marketplace.

via ZeroHedge News http://bit.ly/2Wo3bGU Tyler Durden